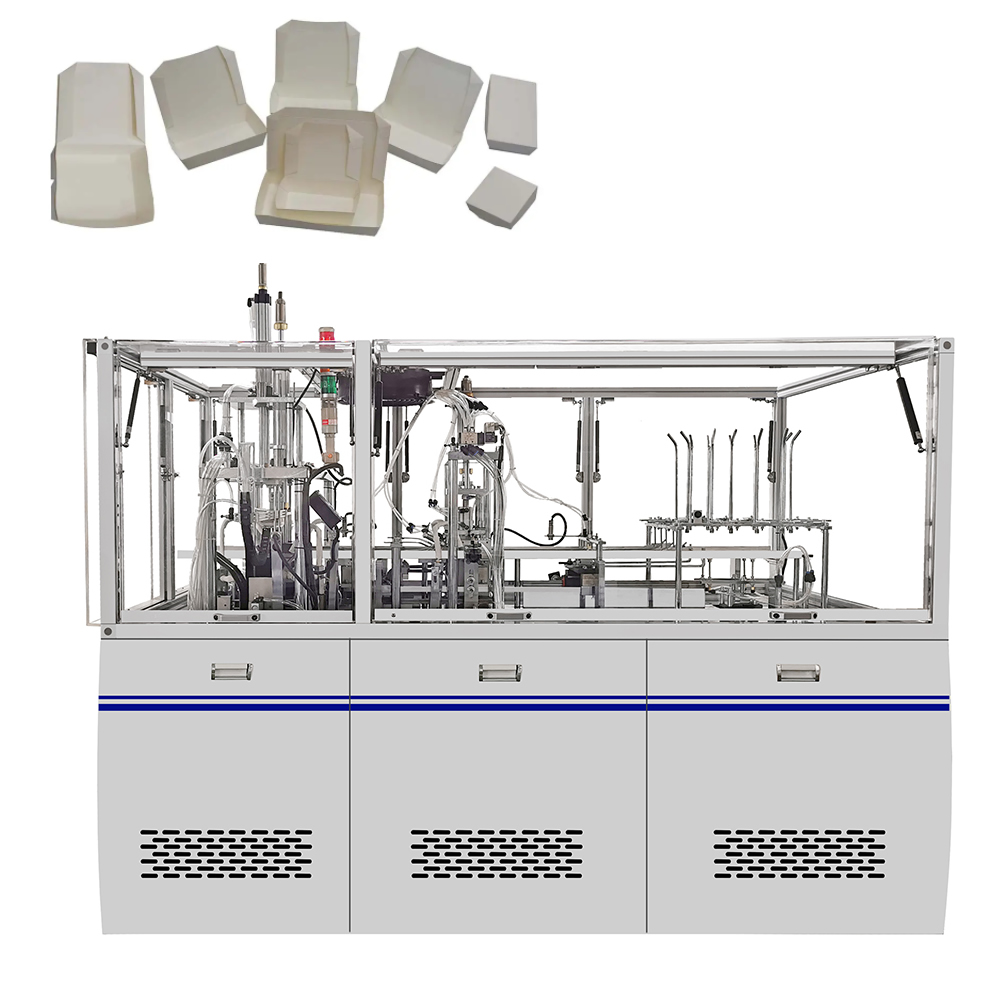

China High Quality 4oz Paper Lid Machinery Manufacturers – X-ZDJ-700 Medium-speed Automatic Paper Plate Machine – Tongzhuo machinery

China High Quality 4oz Paper Lid Machinery Manufacturers – X-ZDJ-700 Medium-speed Automatic Paper Plate Machine – Tongzhuo machinery Detail:

| HS.code | 8441309000 |

| Payment: | 30% deposit in advance, the balance 70% pay by T/T before shipment. |

| Delivery Time: | 25 days at sight the deposit. |

| Package Size: | (L x W x H): 1.7m x 1.7m x 1.9m ; Standard five-lay board Wooden Case |

| Weight: | 1200kg |

| Plate Size | 4-10 inch (molds exchangeable) |

| Speed : | 130 pieces per minute (total two working stations). |

| Material : | Paper/paperboard, Single Aluminum-foil/film coated paper or other (100 – 500gsm); |

| Power: | 3KW, 220V 50Hz or other required; |

| Air source : | Working pressure 0.8Mpa, working air volume 1m3/minute; Should buy air compressor. |

| Working vedio: | Any machine video pls go to youtube to watch: xilezhang1@gmail.com |

Remarks:

Price Given on T/T Payment, Extra USD1000/Shipment For L/C Payment.

Price Term: FOB Ningbo port, China.

Payment: T/T( 30% deposit, 70% before delivery) or L/C.

Lead Time: 20~30 working days at sight the deposit.

Packaging: Seaworthy Wooden Packing.

After Sale Service:

Spare parts guarantee for one year.

Send technician for installation & training, the cost cover by buyer( round tickets, accommodation, an allowance of USD100 a day).

Description:

Process: PreForm paper feeding, Suck paper down, Slide Preform paper to the mold, Press down &heating-forming the shape, Release mold (plate/tray out).

Press and make round, rectangle, irregular, customize shaped paper plates, dishes, trays. Pneumatic Air Cylinder(Piston) provide the press power, Press UP-mold to DOWN-mold. Standard machine press power is 5Tons,

Heater in Down-mold, Make shape nice and hard.

Feature:

With the advanced Program (PLC control the machine processing), High efficient Pressurize Air-Cylinder and Solenoid Valve (imported from Taiwan), Reliable machine design to keep the machine fast speed and durableness.

With the function of fault detection and auto stop, magnet control paper position, etc to get good quality plates and easy maintenance.

Two times pressurizing forming to keep high quality plate/dish shape.

Each working station has separately control.

PLC Program control machine, intelligent, fast speed, easy operate.

Production photos:

Product detail pictures:

Related Product Guide:

The shape of things to come: A consumer’s guide to 3D printers Engadget Engadget save share save share save share save share save share save share Page 1 Page 1 ear icon eye icon Fill 23 text file vr | Cup Printing

‘WAR’ teaser: Hrithik Roshan, Tiger Shroff engage in deadly action stunts | Pla Film Extrusion Machine

Each individual member from our large performance revenue crew values customers' needs and company communication for China High Quality 4oz Paper Lid Machinery Manufacturers – X-ZDJ-700 Medium-speed Automatic Paper Plate Machine – Tongzhuo machinery , The product will supply to all over the world, such as: Johor, Angola, Eindhoven, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.