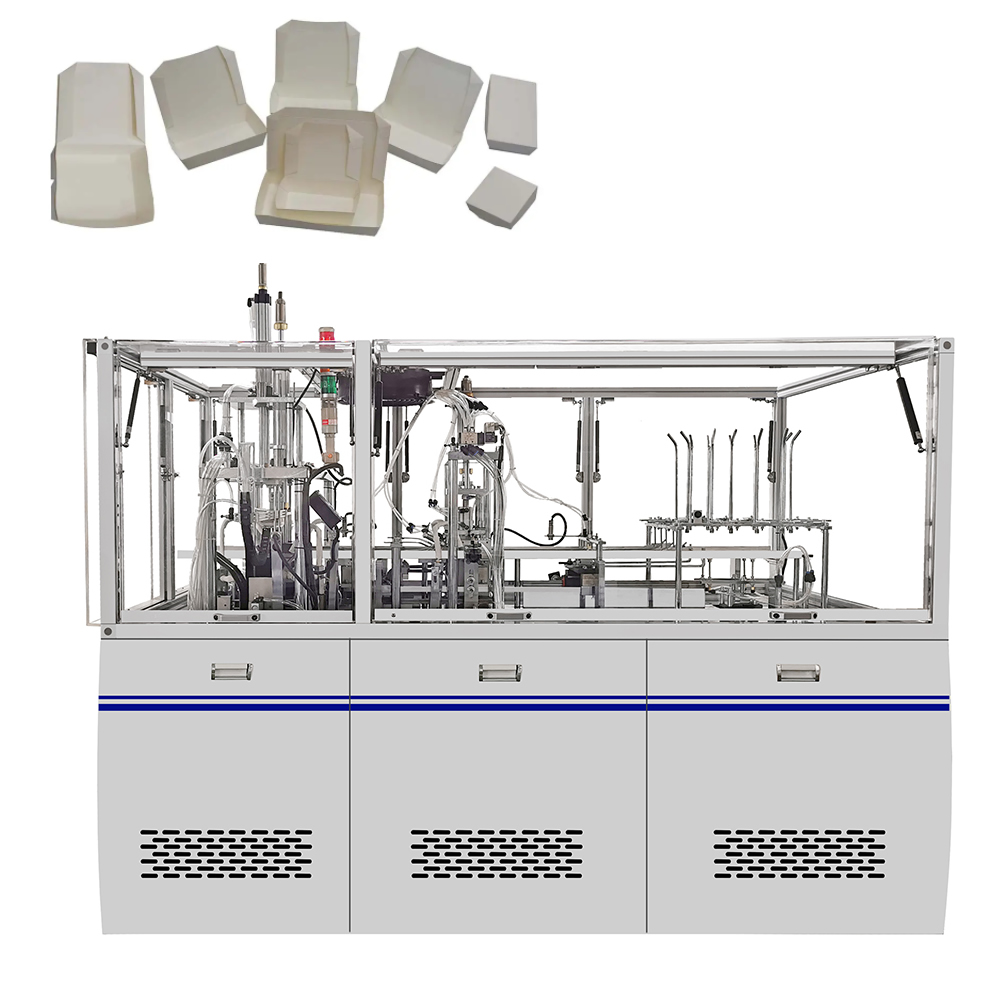

China High Quality Paper Tea Cup Making Machine Manufacturers – FBJ-C Full automatic intellgence paper box forming machine – Tongzhuo machinery

China High Quality Paper Tea Cup Making Machine Manufacturers – FBJ-C Full automatic intellgence paper box forming machine – Tongzhuo machinery Detail:

It Is the automatic paper product molding equipment, combination erf pneumatic and mechanical action. It has the advantages of fast speed, simple operation, high efficiency and environmental protection automatic feeding, hot. pressing, automatic counting and collection, mechanical action Program control and fault monitoring.This type of machine equips with hot air generating device, suitable for single PE coated paper, kraft paper, etc, for the production of single-piece disposable paper lunch boxes covered with lid,paper boxes, kraft paper boxes and other food paper packing box.

| Type | FBJ-C |

| Production capacity | 30-45 pieces/min (Actual production is subject to product size) |

| Maximum paper size | 480X480mm |

| Suitable material | 200-400g/m(PE Coated paper) |

| Total power | 5KW |

| Voltage requirement | 380V/50 HZ (please Inform us your power In advanced) |

| Total weight | 0.7T |

| Overall dimension | 1550(L)X1350(W)X1800(H) mm |

| Gas source requirement | Air pressure 0.4-0.5Mpa (Need to buy air compressor) |

| Working volume | 0.3-0.4m Vm In |

Introduce:

Paper passing and Paper suction through Mechanical transmission ,high speed, energy saving, stability, easy operation

Mechanical operated by microcomputer control and detection, the main electrical control system is imported products, stable and durable

The automatic paper forming equipment has the advantages of high speed and convenient operation. This model uses a self-contained hot air generator for single PE coated paper.Imported Parker rodless cylinders are used. The clamping cylinders are imported UNIQUC cylinders. The mechanical movement is smooth and accurate, and the collector has the function of collecting and counting.

The equipment installation molds are all made of aluminum alloy molds, which are processed by computer milling and wire cutting to ensure the precision of the mold, improve the molding quality of the products, and prolong the life of the mold. The aluminum alloy material has fast heat conduction and reduces heat loss, while the temperature control switch stabilizes the mold temperature saving energy.

The working speed of the equipment is currently 50 times/minute. It is the leading domestic level. It has automatic systems such as feeding monitoring, paper feeding monitoring, molding monitoring, collection monitoring, etc. if appear fault machine will stop and alarm.

Spare parts guarantee for one year in machine arrival. The supplier is responsible for installation, commissioning and training.

Payment method: (domestic)25% Deposit, Before shipment pay 70%, after machine debugging pay 5%(overseas) 25% Deposit, Before shipment and Machine inspection qualified pay the balance

Shipping method and cost: Standard export wooden box packaging, Export to Ningbo or Shanghai port, Freight discuss who burden

4. Delivery time: 30 days

Delivery time: 30 days after receiving the deposit and confirming the draw of the mould

5.Send the technician for installation & training. Buyer bears the cost (round tickets, accommodation)

Technical Specification:

| Type | FBJ-C |

| Production capacity | 35-45times/min |

| Maximum size: | 350x450mm |

| Max Paper Convey Width: | 240mm |

| Suitable Material: | 100-400g/m2 (PE Coated paper) |

| Total Power: | 4KW |

| Total Weight: | 0.8T |

| Overall Dimension: | 1500(L) x1300(W)x2000(H) |

| Working Air Source: | Air pressure 0.4-0.5Mpa (Need to buy compressor) |

Components Brand:

|

Motor |

Main motor |

(CHINA) |

|

Electrical part |

PLC |

INOVANCE(CHINA) |

|

Frequency converter |

INOVANCE(CHINA) |

|

|

Photoelectric switch |

AUTONICS(KOREA) |

|

|

AC contactor |

SCHNEIDER |

|

|

breaker |

SCHNEIDER |

|

|

Photoelectric switch |

AUTONICS |

|

|

Start switch |

AUTONICS |

|

|

Temperature table |

YATAI |

|

|

Pneumatic |

Main cylinder |

AIRTAC(TAIWAN) |

|

Other pneumatic components |

CHINA BRAND |

|

|

other bearings |

HBR |

P.S. If different width, we can do it according to your requirement.

Product detail pictures:

Related Product Guide:

‘WAR’ teaser: Hrithik Roshan, Tiger Shroff engage in deadly action stunts | Pla Film Extrusion Machine

Versatile continuous manufacturing tool | Lab Granulator

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for China High Quality Paper Tea Cup Making Machine Manufacturers – FBJ-C Full automatic intellgence paper box forming machine – Tongzhuo machinery , The product will supply to all over the world, such as: Peru, UAE, Belgium, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!