China High Quality Thermocol Paper Plate Manufacturers – Big Bowl Lid Forming Machine – Tongzhuo machinery

China High Quality Thermocol Paper Plate Manufacturers – Big Bowl Lid Forming Machine – Tongzhuo machinery Detail:

Video

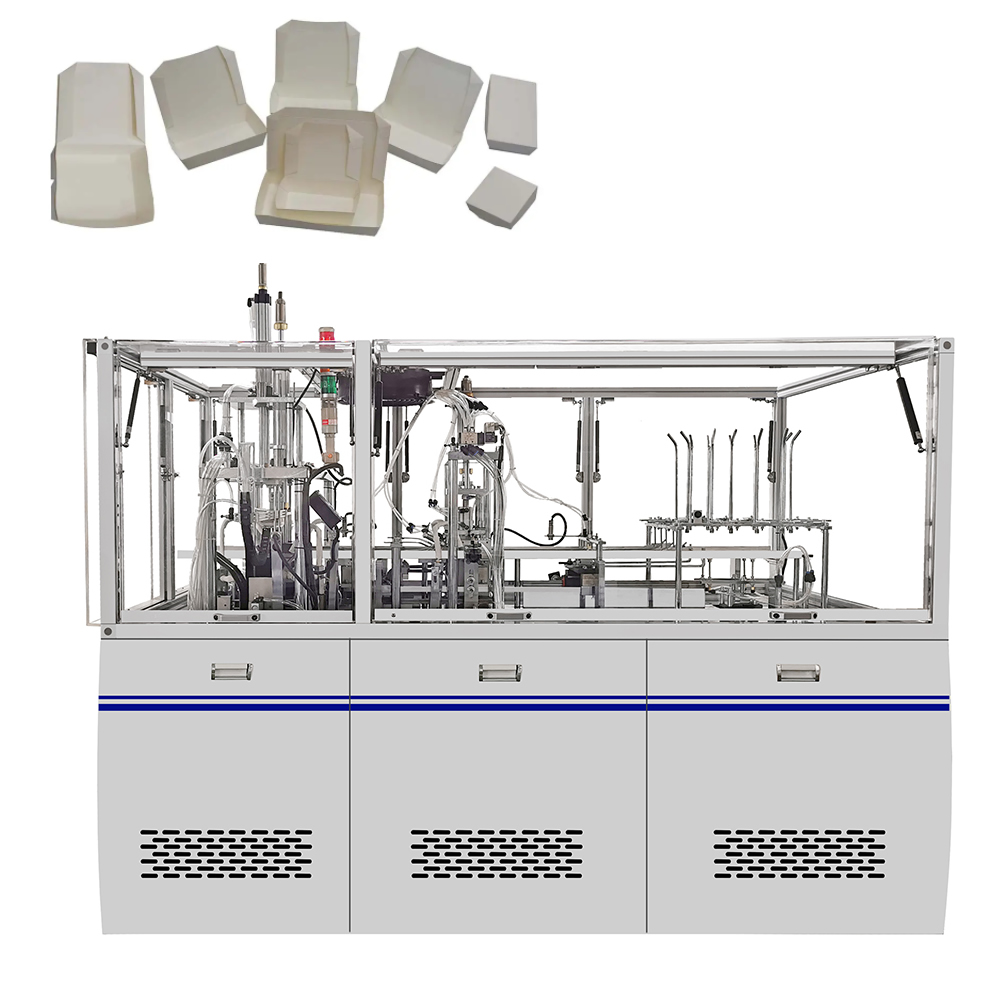

DPJ-100 Single Layer Roll Feeding Cup Lid Forming Machine

DPJ-145 Single Layer Roll Feeding Bowl Lid Forming Machine

DPJ-200 Single Layer Roll Feeding Super Bowl Lid Forming Machine

DPJ-S100 Single-sheet paper feeding cup lid forming machine

DPJ-S145 Single-sheet paper feeding bowl lid forming machine

DPJ-S200 Single-sheet Paper Feeding Super Bowl Lid Forming Machine

1. The single-layer paper cover forming machine series equipment adopts advanced forming technology, which has the advantages of simple operation, easy mold replacement, stable performance, high efficiency, environmental protection and energy saving. According to the different requirements of customers, it adopts automatic roll paper feeding and paper sheet feeding, creasing, embossing, punching, feeding to the mold, heating, crease, knurling, forming and other series of automatic functions. The same mold can achieve different design requirements on the top of the lid by changing the indentation version.

2. The automatic single-layer paper lid forming machine is suitable for lids made of coated paper, ice cream cup lids, coffee cup lids, noodle bowl lids, salad bowl lids, etc. It has largely replaced the plastic cover on the market.

Main Advantages

High speed.

Roll paper/sheet paper (you can choose one of them according to your needs)

Automatic creasing (guide line),

Automatic embossing (the logo and shape on the lid can also be cross-cut),

Automatic punching (cut roll paper into cover),

Cover a piece of paper to save costs.

PLC control + servo motor paper feeding

Open cam + shaft + cam + gear control movement, stable and reliable.

Technical Parameters

|

Customs code |

8441309000 |

|

Paper cover specifications |

Height (8-15) mm, DPJ-100/S100 diameter (60 -100) mm, speed:(70-100) pieces per minute. |

|

Height (8-15) mm, DPJ-145/S145 straight strength (100-140) speed: (60-75) per minute. |

|

|

Height (8-15) mm, DPJ-200/S200 diameter (140 -200) mm, speed:(45-60) pieces/min |

|

|

Applicable paper |

Single and double PE/PLA coated paper, coated paper, glazing coated paper (250-480g/m2) |

|

Power |

10kw |

|

Power supply |

AC380V 3-phase, 50Hz (can be customized according to customers) |

|

Working air source |

Air consumption 0.02 cubic meters per minute, working air pressure 0.3MPa |

|

The total weight of the equipment |

Cup lid machine .2100KG. |

|

Bowl cover machine.2500KG. |

|

|

Giant bowl machine 3300KG. |

|

|

Cup lid machine packaging size |

1920*1640*2000 |

|

Bowl cover machine packaging size |

2200*1880*2100 |

|

Giant bowl lid machine packaging size |

2600*1850*2200 |

Product detail pictures:

Related Product Guide:

We organised a conference for 570 people without using plastic. Here’s how it went | Lab Granulator

‘3D printing offers new opportunities in diagnostics and therapy’ | Pla Film Extrusion Machine

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for China High Quality Thermocol Paper Plate Manufacturers – Big Bowl Lid Forming Machine – Tongzhuo machinery , The product will supply to all over the world, such as: Gabon, Serbia, Panama, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!